Many problems can occur when using locomotives to move railcars. One of the most common problems is misalignment or poor positioning of the railcars. This can cause several issues, including:

- Delays in unloading or loading of the railcars

- Damage to the railcars or equipment

- Injuries to workers

However, in recent years, new technologies have emerged that streamline the railcar positioning process and make it more efficient. One such technology is the railcar mover and positioner. This machinery is designed to quickly and easily move railcars, allowing for more productive operations.

Our railcar movers and positioners can quickly and easily spot cars for loading and unloading, which saves time and money. In addition, our products are tough and durable, so they can withstand the rigors of the railcar handling process.

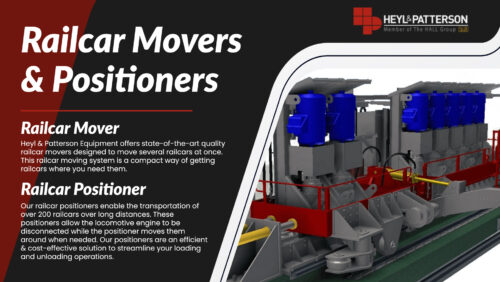

How Heyl & Patterson Railcar Movers and Positioners Work

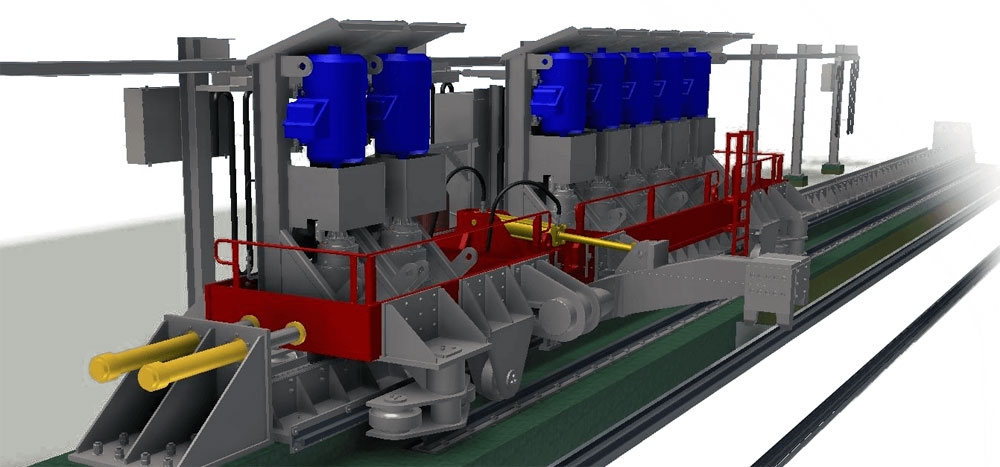

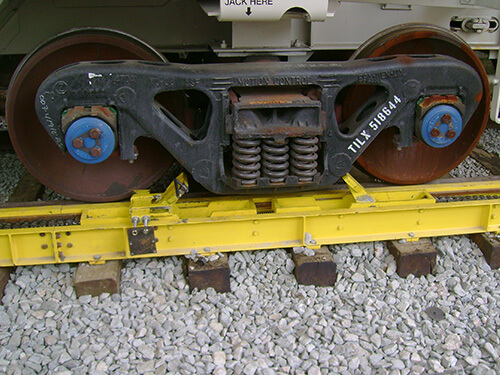

Railcar movers and positioners are specialized equipment for moving railcars short distances. These devices are typically used in different facilities where they must move railcars from one location to another.

Railcar movers and positioners are designed to safely and efficiently move railcars without the need for a full-size locomotive. These devices are available in various sizes and configurations to suit the specific needs of the facility where they will be used. Railcar movers and positioners can be operated manually or by remote control, depending on the operator’s preference.

Heyl & Patterson manufactures a variety of railcar movers and positioners to accommodate the specific needs of customers in different industries. We have over 130 years of experience designing and manufacturing material-handling equipment, and our products are used worldwide.

From lightweight, low-profile units designed for maneuvering in tight spaces to heavy-duty machines capable of moving large loads over long distances, we have a railcar mover to fit your application.

Our electric railcar movers are used to move railcars around a facility and can be used to load and unload trains. Our positioners move railcars into positions for loading and unloading.

All our equipment is built to withstand the rigors of daily use in demanding environments. And our team of experienced engineers is always ready to custom-design a solution to meet your specific needs.

Advantages of railcar movers and positioners

Heyl & Patterson offers a complete line of railcar movers that provide state-of-the-art modern operation and efficiency. Without locomotive assistance, our industrial railcar movers can be used for various loading, unloading, and other types of applications.

- Railcar movers and positioners are much more precise than traditional methods, moving them into the proper position for loading and unloading. This increases efficiency and reduces the chance of damage to railcars.

- Railcar movers and positioners are also much safer than traditional methods of railcar movement. Safer than winch systems, which can cause injury to workers from the snapped rope.

Overall, railcar movers and positioners offer several advantages over traditional methods of railcar movement. They are faster, more precise, and safer, and they can greatly improve the efficiency of rail car handling operations. Our industrial railcar movers and positioners may be the perfect solution to streamline your processes.

Heyl & Patterson is the only railcar mover you’ll ever need

Heyl & Patterson railcar movers and positioners are designed for a variety of applications, including:

- Loading and unloading railcars

- Shunting railcars

- Positioning railcars for maintenance and repair

- Moving railcars in and out of storage

- And more!

If you’re searching for a railcar positioning engineer, Heyl & Patterson is the perfect partner. We have a wide range of products to choose from, and our team can help you find the right solution for your needs. Contact us today to learn more about our industrial railcar movers and positioners or to request a quote.