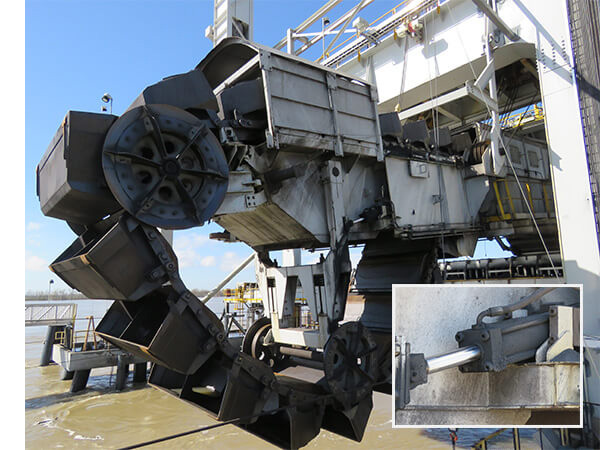

Mechanical Upgrades

Heyl & Patterson’s mechanical upgrades increase and significantly enhance wear life and decrease downtime. Unloader integrity and dependability is crucial to your job’s productivity. Our complete line of modifications include:

Equalized Trolley Wheels – Reduce wheel loads by 50%, thereby reducing stress on girders, preventing cracking and promoting longer life.

Buckets – Our efficient product-specific designs include stronger materials that wear better.

Auto–Lube System – Environmentally friendly, our system lubricates more consistently and safely with “green” lubricants currently available.

Trolley Rack Rope Take-Up Device – Redesigned for greater efficiency unloader movement.

Flexible Nose Spring Assembly – Upgraded heavy-duty shock absorbing system.

Return Chute Wear Liners – Able to endure higher abrasion levels, thereby enabling longer life.

Tail and Pivot Shaft – Timken heavy-duty AP bearings to replace pillow block style bearings.

Pivot Shaft Take-Ups – Actuated with hydraulic cylinders on both sides of the boom.

Trolley Drive Shaft – Our revamped style extends life with dual line shaft set-up.

Chain Rollers – An upgraded design, with better seals and rebuildable/replaceable components.

Service Crane Retro Fit – Enlarged to accommodate 1 to 15-ton capacity.

Bucket Drive Upgrades, which include:

- Complete upgraded boom replacement.

- Replaceable tooth sprockets change teeth and not the whole sprocket. Teeth can be purchased separately.

- Chain-greaseable or permanently greased design available.

- Head shaft design is improved in composition and profile.

- Bucket drive gear case upgrade, auto-lube on pinion/intermediate gears.

- Drive pinion support structures upgraded design.

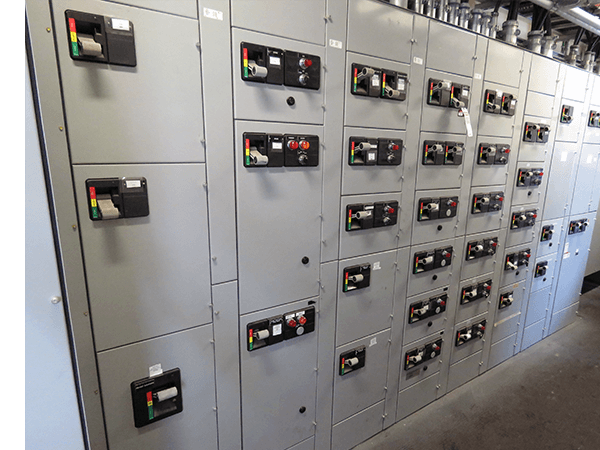

Electrical Upgrades

Heyl & Patterson’s CBU electrical upgrades are energized for economy and efficiency. our electrical upgrades can further extend the service life of your CBU with improvements that reduce maintenance time and costs, provide greater performance output and smoother operation. Our complete line of upgrades include:

Control Upgrades – Featuring:

- Variable Frequency Drive (VFD) to increase the lifespan of electrical/mechanical components to dramatically extend motor operation

- Operator Control of unloading speed

- Control Cab HMI to monitor drive data

- Digital drives in AC or DC combination

- Control upgrade

- Digital signal processor to coordinate each drive for peak performance and operation

Fiber Optic Cabling – For motor drives.

Digital-Based Data Collection and Troubleshooting and Remote Monitoring – Intuitive software control automatically assesses and addresses system/machine alerts and errors remotely.

Boom Hoist VFD

Trolley Auto Sweep Control

Barge Haul Control VFD

Positioner Stem Slack-Rope Switch

Disc Brakes – For Barge Haul, Trolley, Boom Hoist and Bucket Drive

Closed Circuit Monitoring Historian – Problem-tracking/performance evaluation through cameras that document operating conditions.