Material Handling Equipment for Specialized Needs

Hammermill

The innovative Heyl & Patterson Hammermill is your answer to frozen and oversize material that hamper your railcar unloading process. The safe, rugged, energy efficient hammermill helps clear frozen materials from clogged grates and grizzlies, eliminating the need for expensive crushing equipment and keeping site personnel out of hazardous areas. The labor intensive, dangerous job of manually cleaning the grizzly is eliminated.

The traveling hammermill traverses the hopper beneath the railcar dumper in order to clear the material from the grates or grizzlies. Adaptable into a new or existing facility, the Hammermill can be used in conjunction with other manufacturers’ rotary car dumpers without excessive downtime for installation, and with fuel efficiency and cost savings unmatched by the competition.

Proven to clear blockages efficiently, with travel speeds of up to 30 feet per minute in normal operation, allowing you to get back to the unloading process. Unloading production is maximized with the hammermill, allowing for operation 12 months a year. We have installed the Hammermill onto Heyl & Patterson designed machines as well as Rotary Dumpers manufactured by others manufacturers worldwide.

Reduce downtime. Increase safety. Increase production. Utilize the hammermill to achieve your operating goals.

Click here to learn more about Hammermill

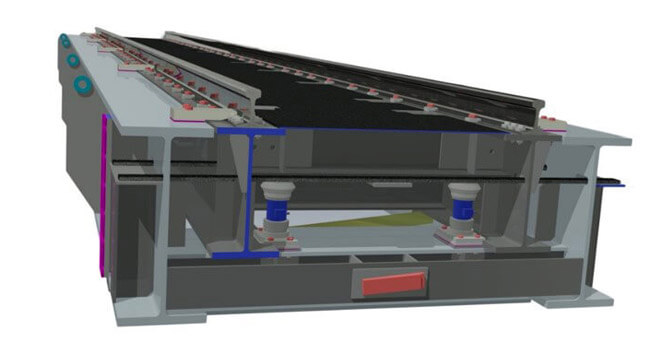

In-Platen Weigh Scales

Heyl & Patterson’s platen weigh scales can be installed in new dumper systems or retrofitted in an existing dumper. Designed to record the weight of each rail car and its contents, it uses the latest technological innovations for up-to-date reliability and ease of operation.

Weights for all cars are recorded automatically, without impact on cycle time, meeting accuracy tolerances & NTEP specifications. Heyl & Patterson is proud to offer the only in-platen NTEP-certified weigh scale. NTEP (National Type Evaluation Program) is a strict product certification standard administered by the National Conference on Weights and Measures.

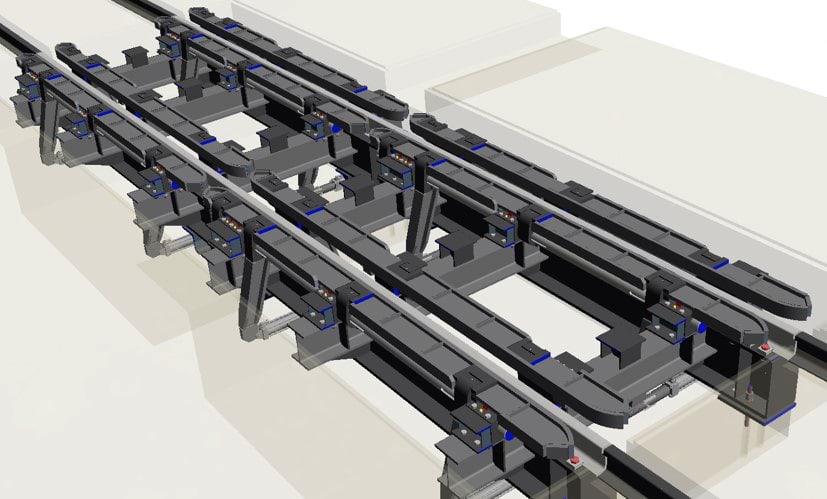

Train Holding Devices

Heyl & Patterson’s train holding devices control the train as the positioner moves in the reverse direction and keep railcars secure during the dumping cycle. The devices allow the user to maintain complete control of the train while isolating the train forces from the car couplers. This becomes especially useful anywhere in which automatic and semi-automatic dumper operations are required for use with both empty and loaded railcars.

- Wheel Chocks – Perfect holding device for level track conditions.

- A-Style – light duty, holds a single two wheels on one axle

- B-style – heavy duty, holds entire truck assembly on both sides, corrects misspots

- Grippers – Used for fast actuation, allows for slight miss spotting while gripping both sides of each wheel on one truck. Multiple grippers can be installed in series.

- Holding Arm – Provides the most holding force by grabbing the coupler. Best for large car strings and challenging track profiles.

- Retarders/Ejectors – Typically installed on the platen that is used on random car dumpers to slow and stop slow-moving railcars by applying friction on one side of each wheel. Ejectors move single railcars off of the platen and out of the dumper.